VIRTUAL SENSORS FOR MOBILITY

-

Purely software-based

-

For any kind of vehicle

-

Cloud-based or in-vehicle

VIRTUAL SENSORS – THE FUTURE OF MOBILITY

Our approach combines years of automotive and durability expertise with state-of-the art data science.

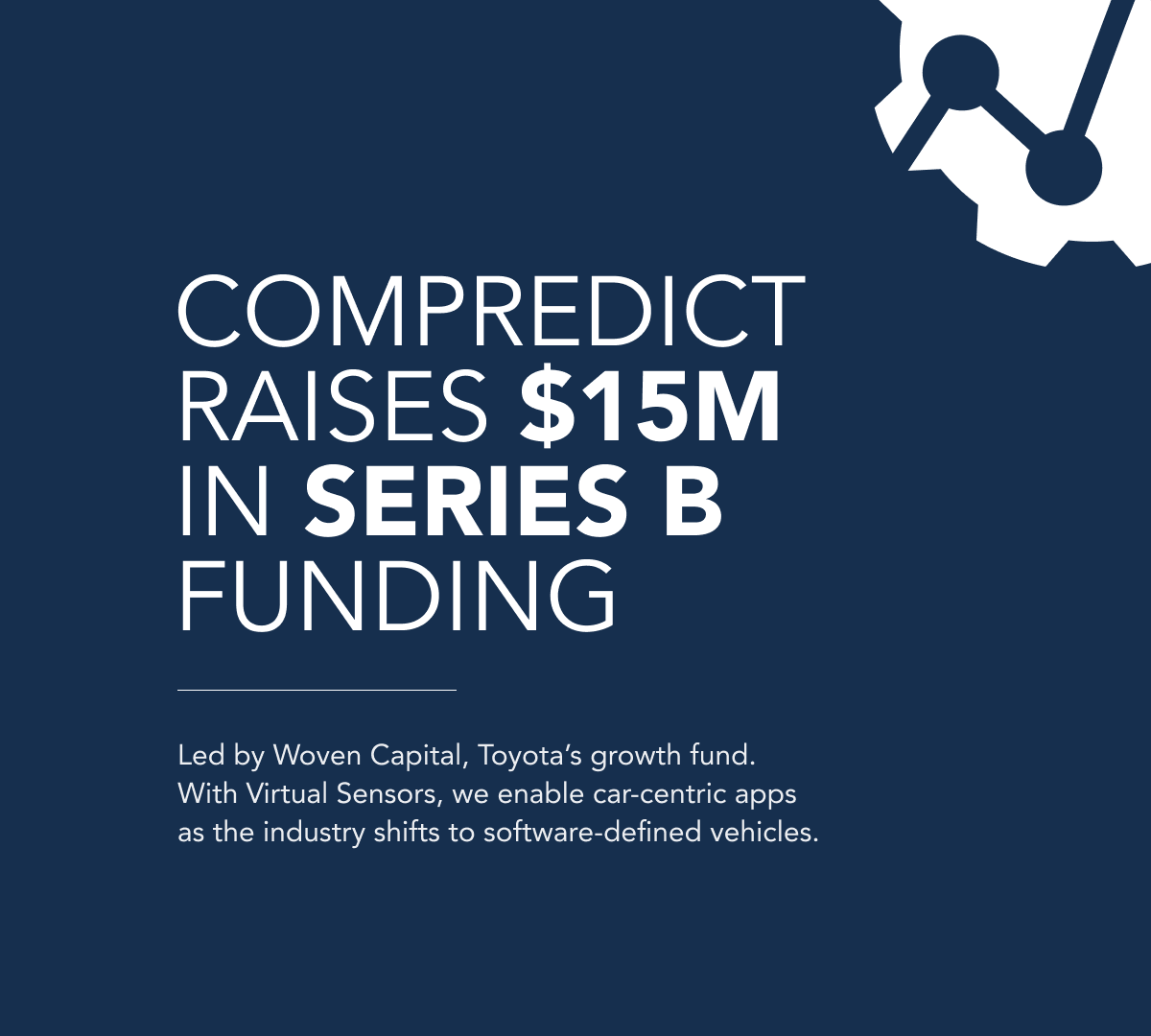

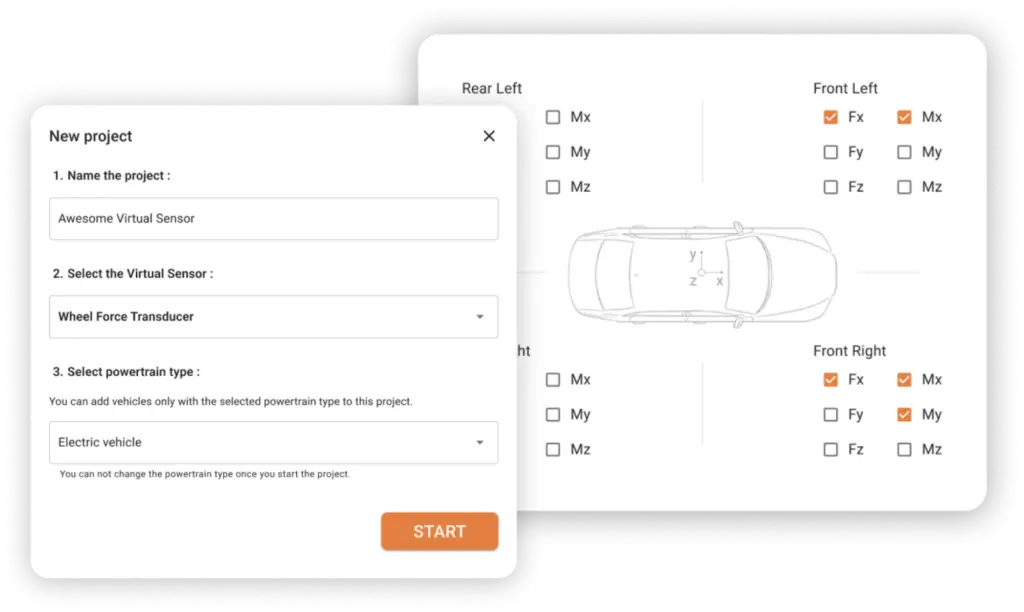

Virtual Sensor Platform

The #1 platform for Virtual Sensor Management in the Automotive Industry

INDUSTRIES

CURRENT NEWS AND EVENTS

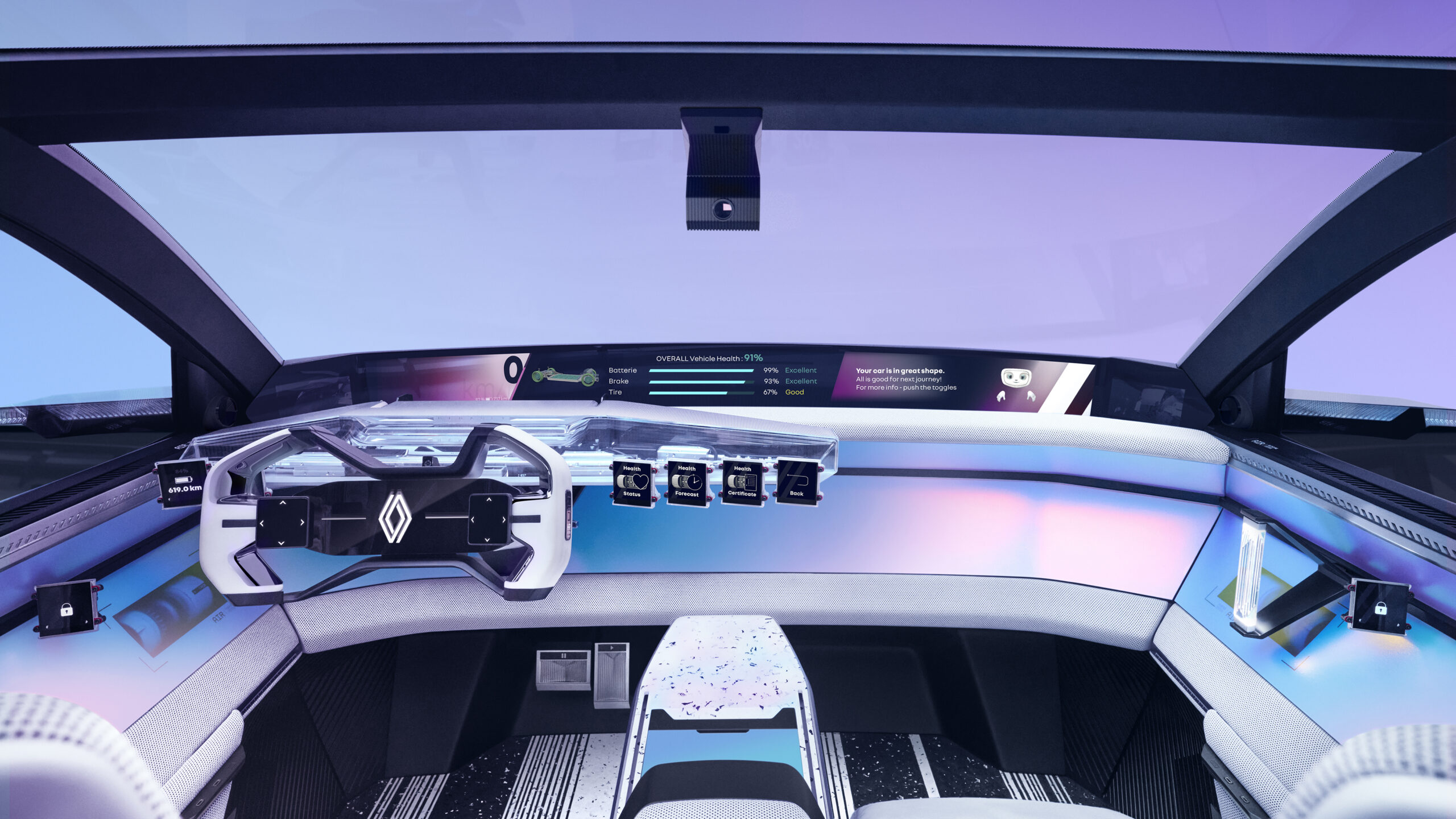

COMPREDICT and Renault Group Announce Landmark Partnership for Predictive Maintenance Technology

Latest News COMPREDICT and Renault Group Announce Landmark Partnership…

COMPREDICT Revolutionizes Mobility Industry with Cutting-Edge Solutions in the H1st Vision Car at VivaTech 2023

Collaborating with Renault and Software République, COMPREDICT Showcases Innovation…

OUR PARTNERS

At COMPREDICT, our expertise is amplified through strategic alliances with global industry leaders. Our robust partner network is more than a collection of names; it’s a dynamic ecosystem where each entity brings unique strengths to the table.

Together, we’re not just building cars; we’re shaping the future of mobility.